Linear technology for flexible assembly lines

Linear technology for flexible assembly lines

Linear technology for flexible assembly lines

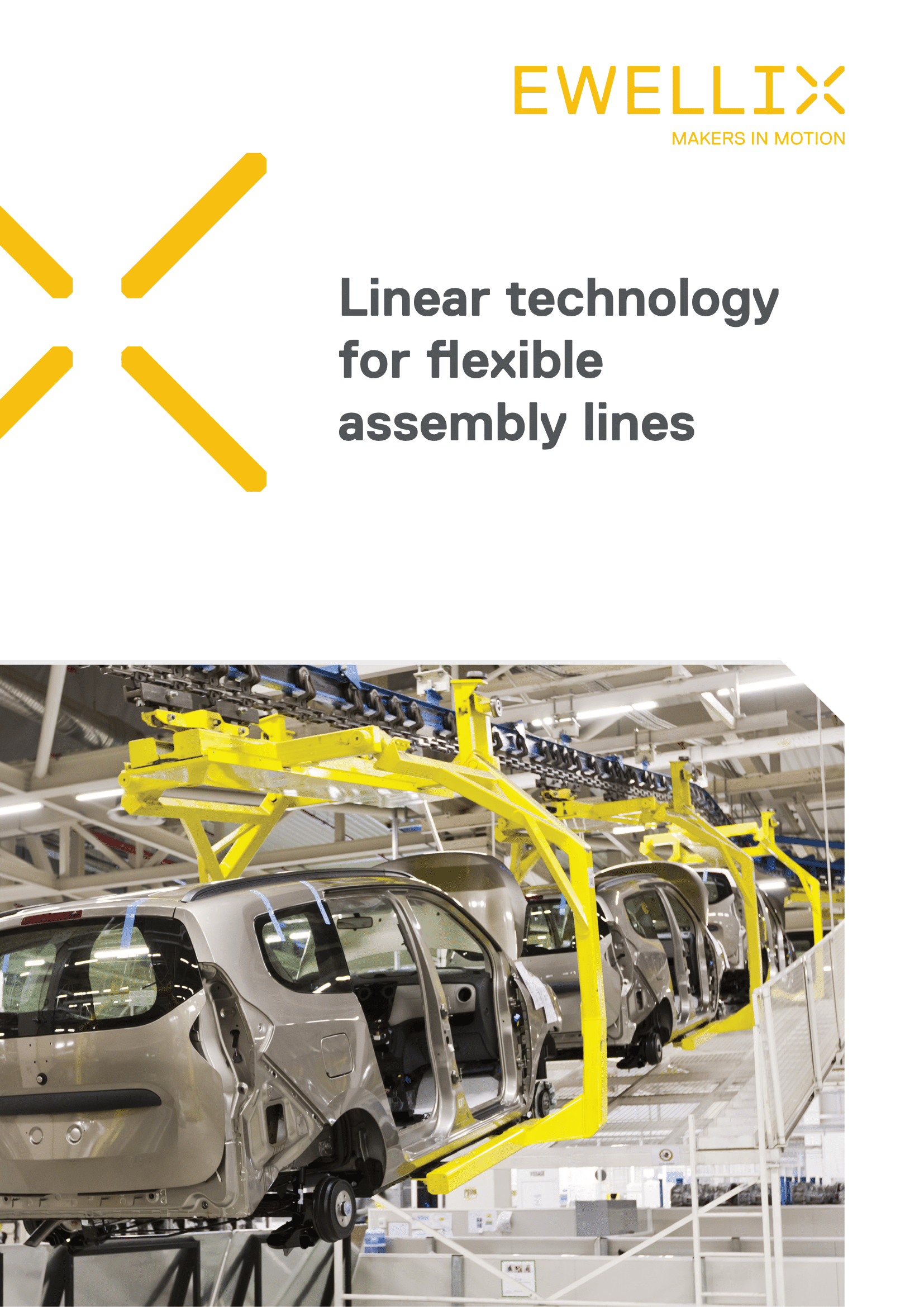

In a fast-changing industry with new car technologies, electrification and embedded advanced software, automotive production lines must be highly flexible and adaptable to remain competitive and cost-effective.

Flexibility

Equipment needs to be repurposed with minimal changes or additional investment costs

Modularity

Switch from conventional ‘long line’ production to manufacturing cells

Productivity

Lean production lines for various models, limiting the footprint and downtime in resetting the line

See how the Car Transfer Unit works

The Car Transfer Unit (CTU) can be quickly reconfigured to transport different car models on a single assembly line. Compared to the use of conventional assembly equipment and tools, the use of CTU reduces the amount of reprogramming and commissioning, improving flexibility of automotive production line.

Value proposition

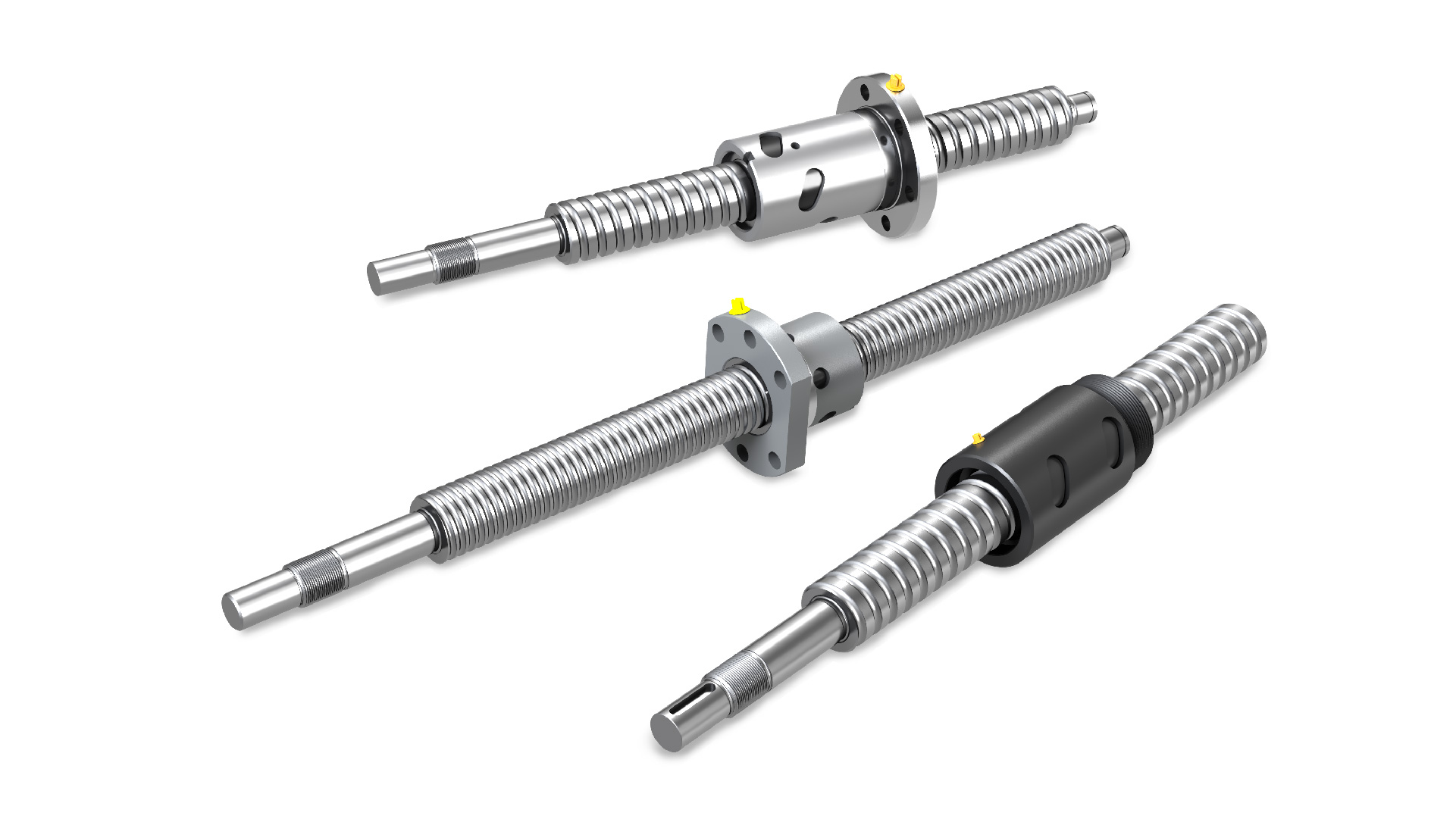

We support our customer’s evolution with state-of-the-art linear technology, i.e.,

powerful ball and roller screws and high-quality linear guides integrated with

engineered systems.

Industry target

Ewellix solutions

Improve asset reliability

Minimise system footprint, space and weight

Increase productivity

Enhance performance and programmability

for precise, predictable, and repeatable motion

Optimised design

Customizable reconfigurability with multiple

options

Reduce energy consumption

Elevate the solution with optimized efficiency

Decrease maintenance costs

Decrease downtime and installation time with flexible

systems

Return of investment with flexible production lines

Return of investment with flexible production lines

Return of investment with flexible production lines

Smart production and logistics systems combine modularity and intelligent automation to allow maximum flexibility. Focusing on flexibility allows companies to adapt continuously, leading to cost-efficient production cells and significant savings.

Smart production and logistics systems combine modularity and intelligent automation to allow maximum flexibility. Focusing on flexibility allows companies to adapt continuously, leading to cost-efficient production cells and significant savings.

Smart production and logistics systems combine modularity and intelligent automation to allow maximum flexibility. Focusing on flexibility allows companies to adapt continuously, leading to cost-efficient production cells and significant savings.

Main parameters driving the result

• Quantity of flexible systems

• Investment per flexible system

• Number of car models produced over 15 years

Besides cost savings, flexible systems lead to time saving when resetting an assembly cell from one car model to another. See image.

Fixed system versus flexible system:

optimisation of the resetting of the assembly cell

Discover our solutions

We have various solutions to assist automotive manufacturers with an easy integration.

Discover the benefits and ask for more information!

Posizione assoluta

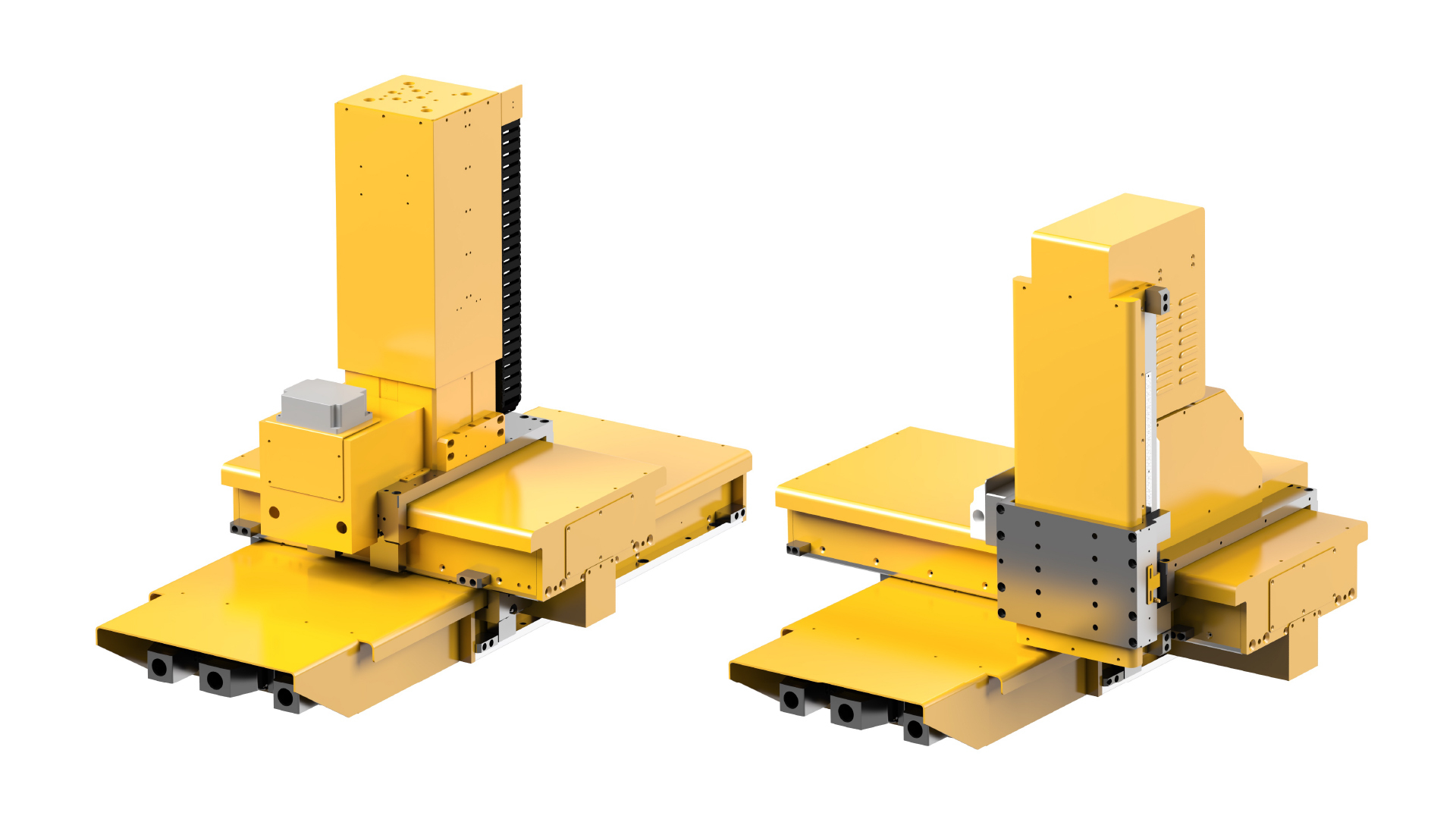

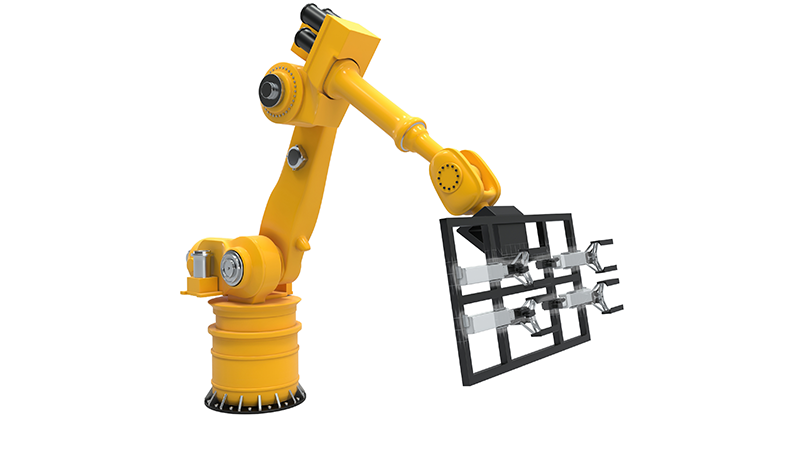

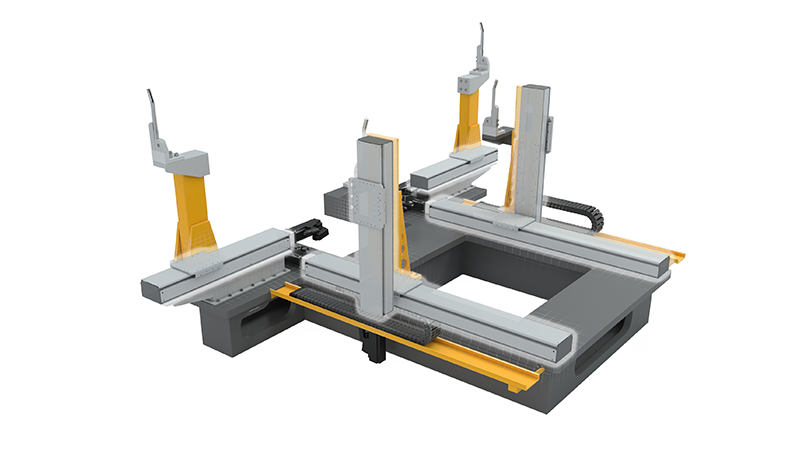

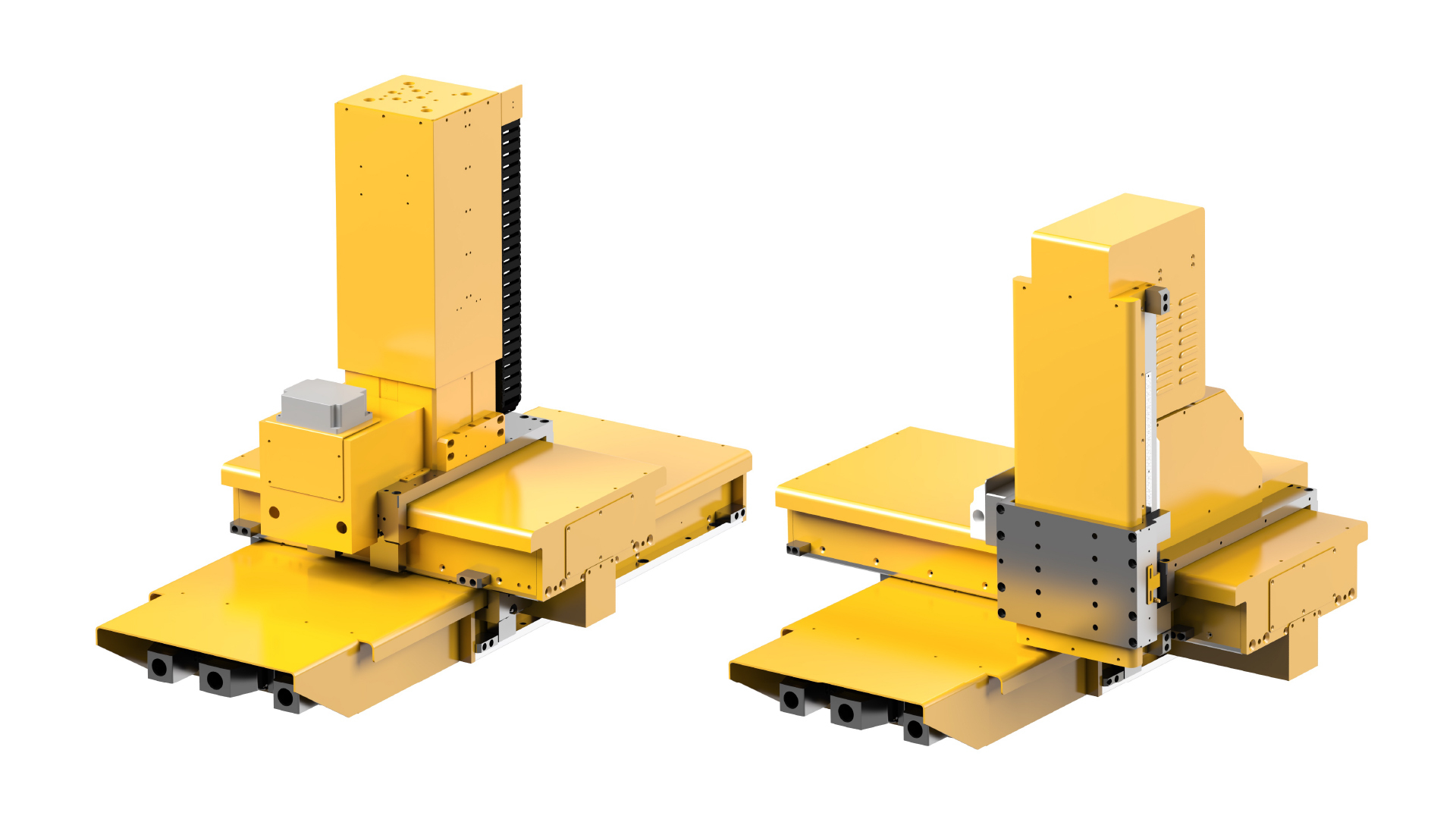

Positioning system Car Transfer Unit (CTU)

Light Car Transfer Unit (LCTU)

Typically used for the welding process on the BIW shuttle line and is located outside the shuttle, providing:

- High speed

- High dynamic load capacity

Heavy Car Transfer Unit (HCTU)

Typically used for the welding process on BIW pallets and is located on a moving pallet (under BIW), providing:

- Low retracted length

- High static load capacity

Positioning system Car Transfer Unit (CTU)

Specifically designed for the automotive industry, they provide high performance in terms of guiding accuracy and stiffness. They are available with lifting columns or linear modules for the additional vertical axis.

Benefits

- Made for long service life and high loads

- Easy maintenance through outside lubrication port

- Precise alignment and secure fastening of attachments

- High precision in positioning and repeatability

Posizione assoluta

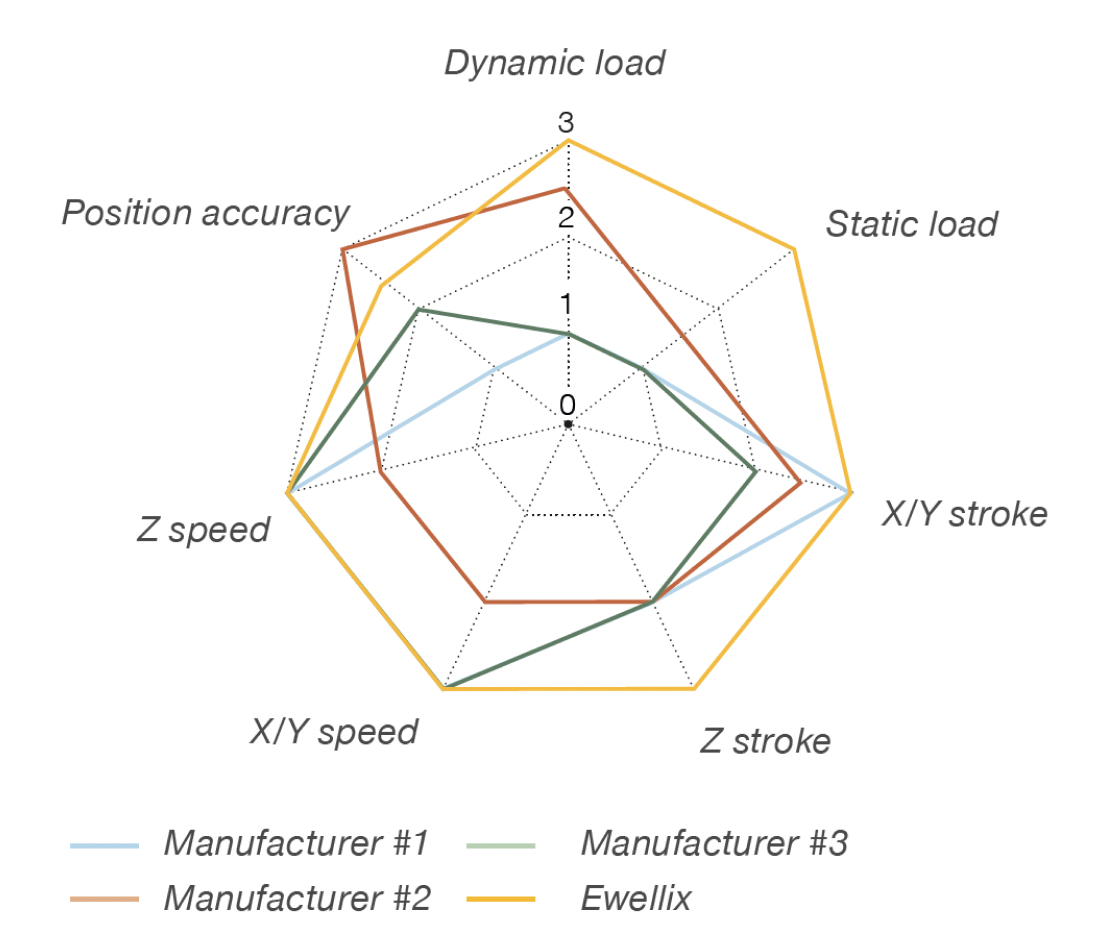

Multi axis transfer units chart

Posizione assoluta

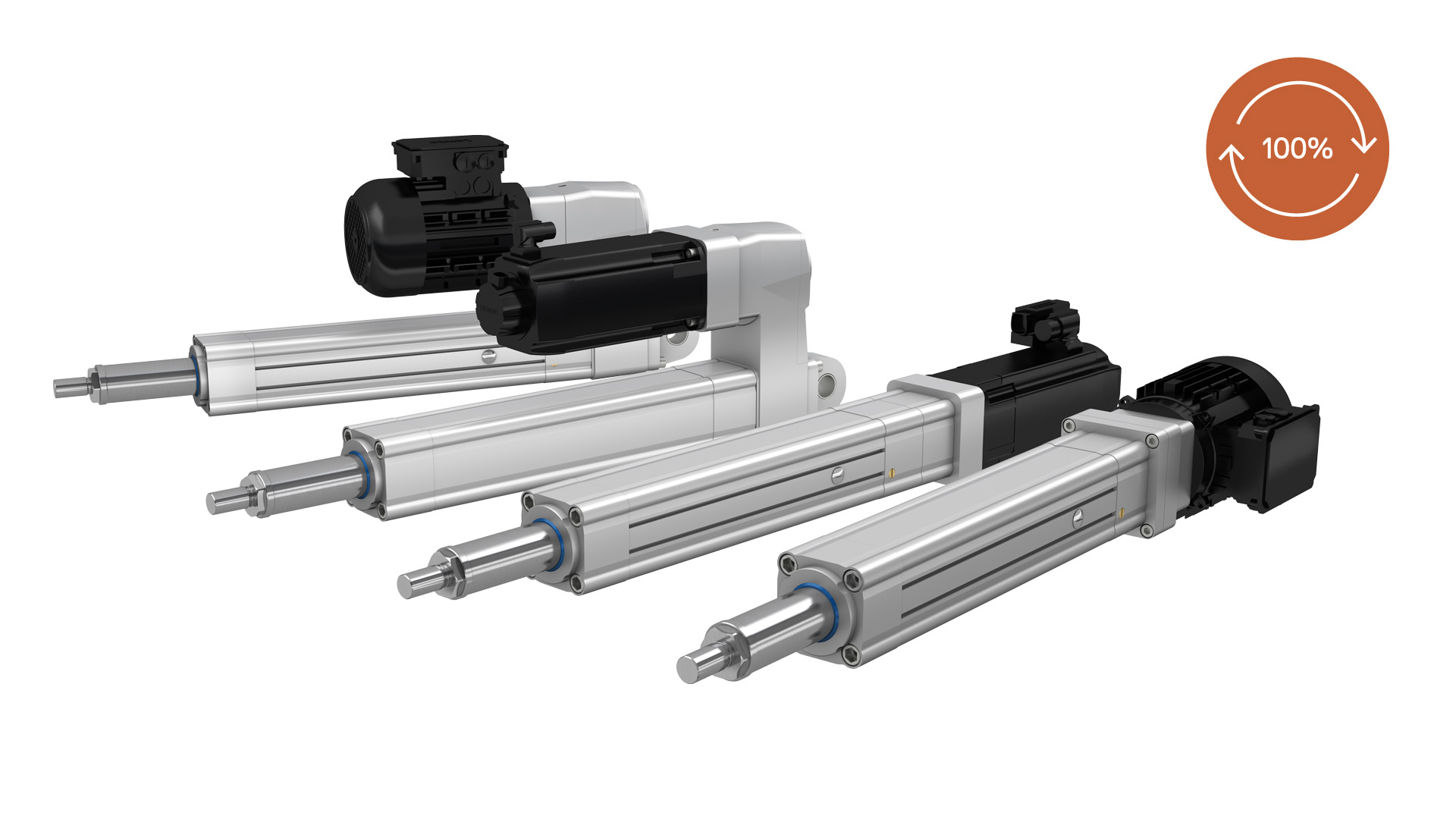

Linear modules CLSM

CLSM 92 and 150

The CLSM linear modules perfectly meet the automotive requirements providing:

- Heavy load carrying capabilities

- Stainless Steel cover for anti-spatter

Linear modules CLSM

Specially designed for automation and automotive applications to follow industry needs in robust, adaptable, and flexible systems.

Benefits

- Long service life

- Precision alignment and secure clamping

- High level of accuracy and repeatability

- Fits most brushless DC motors and servo-motors

- Easy maintenance by one-point lubrication

Listen to what our customers say

Products

Applications

Publications

Video

Discover our field of innovation

Do you have any questions?

Contact our experts.

Fill in the form with your contact and briefly explain your request. We will contact you soon.